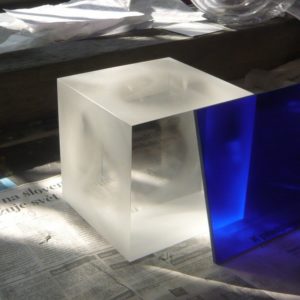

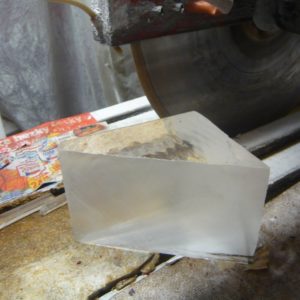

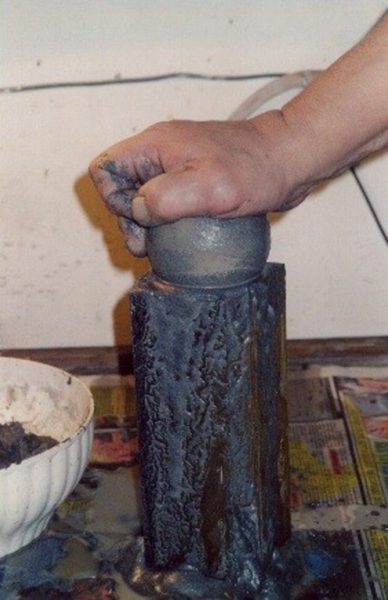

If you aren’t glass experts, then expression such as level, vertical grinding, roughing, perching, smoothing and similar might sound like questions from a TV game show to you. For us however; these things are everyday reality and we proudly use these traditional and demanding manual glass making and shaping techniques. We offer you quality achieved by procedures jealously protected by the best glass artists in their studios. Our studio is open to your ideas and we are ready to shape anything that you might have in mind by grinding it from glass or crystal. You can even try yourselves this traditional craft under the supervision of our experienced glass grinders. It is an adrenaline experience comparable to a tandem parachute jump – just a bit less dangerous. It could also be a good idea for your corporate team-building event after which you will be able to relish the results of your artistic pursuit and give one another compliments in our gallery. Who would resist?

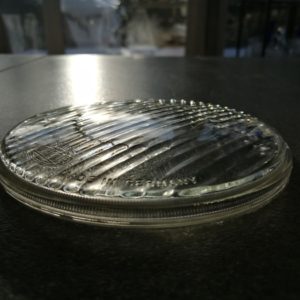

Finally; a few words on the technology nevertheless. Each square centimetre of the ground surface also needs manual polishing. This procedure might be skimped in many glass studios. However; the only way of achieving true brilliance is by careful polishing the finished piece by volcanic pumice-stone attached to a poplar-wood disk and then carrying out after-polish by extremely fine sulphur dioxide powder applied to a felt disk made of cow’s or camel’s hair. Then the result is perfect. This is the way we manufacture in ASTERA.